Deadhead miles, or "empty miles," refer to the miles a truck travels without actual cargo. These miles accrue between a load's drop-off location and either another load's pick-up location or the truck's point of origin.

Deadhead mileage is an essential metric in the trucking industry for determining truck and overall fleet utilization.

35% of miles driven by trucks in 2021 were empty miles. 24% of private fleet carriers, 14.8% of non-tanker carriers, and 44.9% of tanker carriers racked up deadhead miles.

These stats are trending down from previous years. Carriers are trying to cut deadhead miles amid rising operating costs and environmental concerns.

Operators, retailers, customers, and the general population feel the effects of deadhead miles. It's a wide-scale problem affecting profitability, safety, sustainability, and efficiency.

So what are the effects of deadhead miles, and how do you minimize them? This article will dive deeply into this vital topic.

The cost of deadhead miles

Deadhead mileage affects major trucking companies, private fleets, owner-operators, and independent contractors. The effects of deadhead miles also spread throughout the supply chain.

Deadheading is expensive

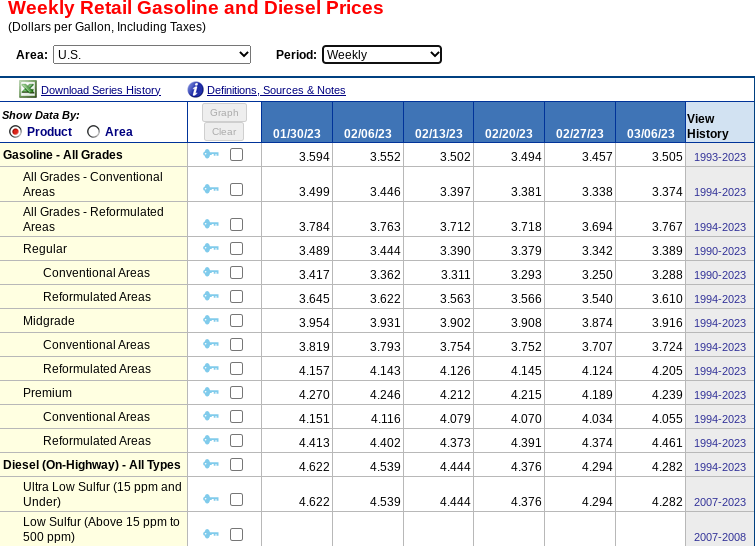

An empty truck still needs gas. Driving for the legal limit of 11 hours a day, at the average truck speed limit of around 65mph, a driver covers about 715 miles daily.

Considering the 6.65 average MPG for a tractor truck in 2021, the driver consumes 107.5 gallons of diesel daily. The average semi's fuel tank holds between 120 and 150 gallons. Since they typically have two fuel tanks, the max capacity is about 300 gallons.

So the driver drains almost one tank in a single day. If the truck has one tank, it'll need refilling daily — with two tanks, the trucker can refill every other day. Refueling costs $642/day at the current diesel cost of $4.28/gallon.

So driving around 60,000 miles/year equals about $38,617/year in fuel costs, including the $13,516 it costs to drive 21,000 deadhead miles.

Equipment wear and tear is another cost to consider. A deadhead truck still accumulates miles, wears down its tires, and needs maintenance and repairs.

Finally, truck drivers need compensation, even if the truck is empty. Company drivers receive this in their hourly wages or salaries, which means the company eats the cost of deadheading.

While not required, some carriers do compensate independent contractors and owner-operators for empty miles:

Whether the driver or the carrier swallows deadhead expenses, they offset those expenses in the fee negotiation. As such, the costs get passed down to shippers, manufacturers, and retailers. These passed-on costs can even result in higher prices for customers.

Deadheading is dangerous

Unlike bobtailing, when the truck's cab has no attachment, a deadheading truck poses far greater safety risks. The empty trailer or flatbed becomes a hazard in adverse weather.

The empty attachment can act as a sail in strong wind conditions, making the truck more susceptible to swerving or flipping. Driving an empty truck is also hazardous on roads slick from ice, rain, or snow.

Truckers have to be especially attentive to severe weather warnings and traffic reports if they'll be deadheading. Reports will often warn truckers of high wind speeds or adverse weather conditions, like these warnings to truckers traveling in dangerous conditions around the southwest.

The weight discrepancy from a full trailer to an empty one is hard to maneuver, especially during difficult road and weather conditions. Even seasoned deadhead drivers struggle with this. But drivers without training or varied experiences with deadheading wrestle with it even more.

In 2020, 439,000 large trucks were involved in traffic crashes in the US. 107,000 crashes involved injuries, and 4,842 trucks were involved in fatal crashes. A deadly accident involving two empty trucks occurred in Missouri just last month.

Full trucks contribute to road safety for truck drivers and those on the road around them.

Deadheading is hazardous to the environment

Truck deadheading also releases extra, unnecessary carbon dioxide emissions into the air.

North America accounted for 30% of global transportation emissions in 2021. It produced 2 billion metric tons of carbon dioxide emissions. That's the second-highest contribution to global transportation emissions after the Asia-Pacific region.

The US transportation industry creates considerable carbon emissions all on its own. For over three decades, it’s produced far more annual carbon emissions than any other country. In 2021, it released 1.65 billion metric tons of CO2 emissions.

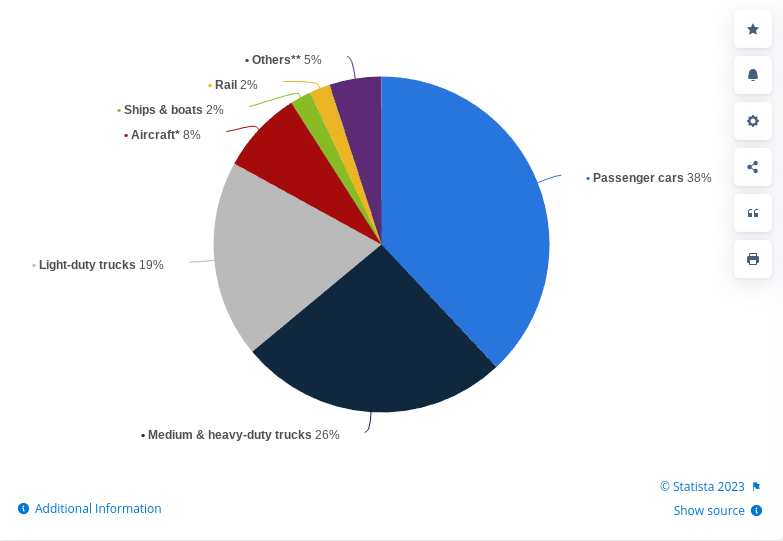

Medium and heavy trucks together form the second-largest source of transportation emissions in the US. While fewer trucks populate the road than passenger vehicles, they're much larger and rap far more mileage.

Trucking is crucial to world commerce. Everything we own was at one point in a box in the back of a truck during its product journey. But optimizing trips to cut deadhead miles could at least decrease CO2 emissions.

Consumers are concerned about the environmental impact of their deliveries as well. 20% of global consumers will pay more for a delivery from an environmentally-friendly company. 37% consider convenience and sustainability equally important.

79% of consumers will change their purchase preferences based on environmental impact.

Deadheading is inefficient

A truck carrying empty cargo for hours and miles, earning little or no revenue, is textbook inefficiency. Drivers, shippers, and consumers could profit from those miles. The time and truck capacity wasted on deadheading could go to better use.

Instead, the time spent by fleets of deadheading trucks impacts delivery times. If not for wasteful deadhead miles, customers could enjoy shorter delivery windows, which is highly important to them.

Trucks also get delayed when they deadhead in adverse weather and road conditions or reroute to avoid those conditions. Shipping delays result, which affects on-time delivery.

Delays can also occur when drivers reject loads because of deadhead mileage and the corresponding profit loss. While some carriers compensate independent contractors and owner-operators for deadhead miles, most don't.

How to reduce deadhead miles

Reducing deadhead miles requires careful planning, increased route visibility, and clear communication. You'll also need a tech solution to help orchestrate it all.

This is where third-party logistics (3PL) providers such as Delivery Solutions come in. They perform, automate, and streamline the work needed to cut deadhead miles.

Keep trucks full by backhauling

Backhauling is critical for decreasing deadhead miles and keeping trucks full. Securing a backhaul from a drop-off location or on the way to it maximizes the route's profitability and cuts deadhead.

Retailers can build backhaul strategies to optimize delivery routes to their greatest advantage. For example, through its backhaul program, CVS Health cut 500,000 empty miles in 2021 and over 2 million since 2018.

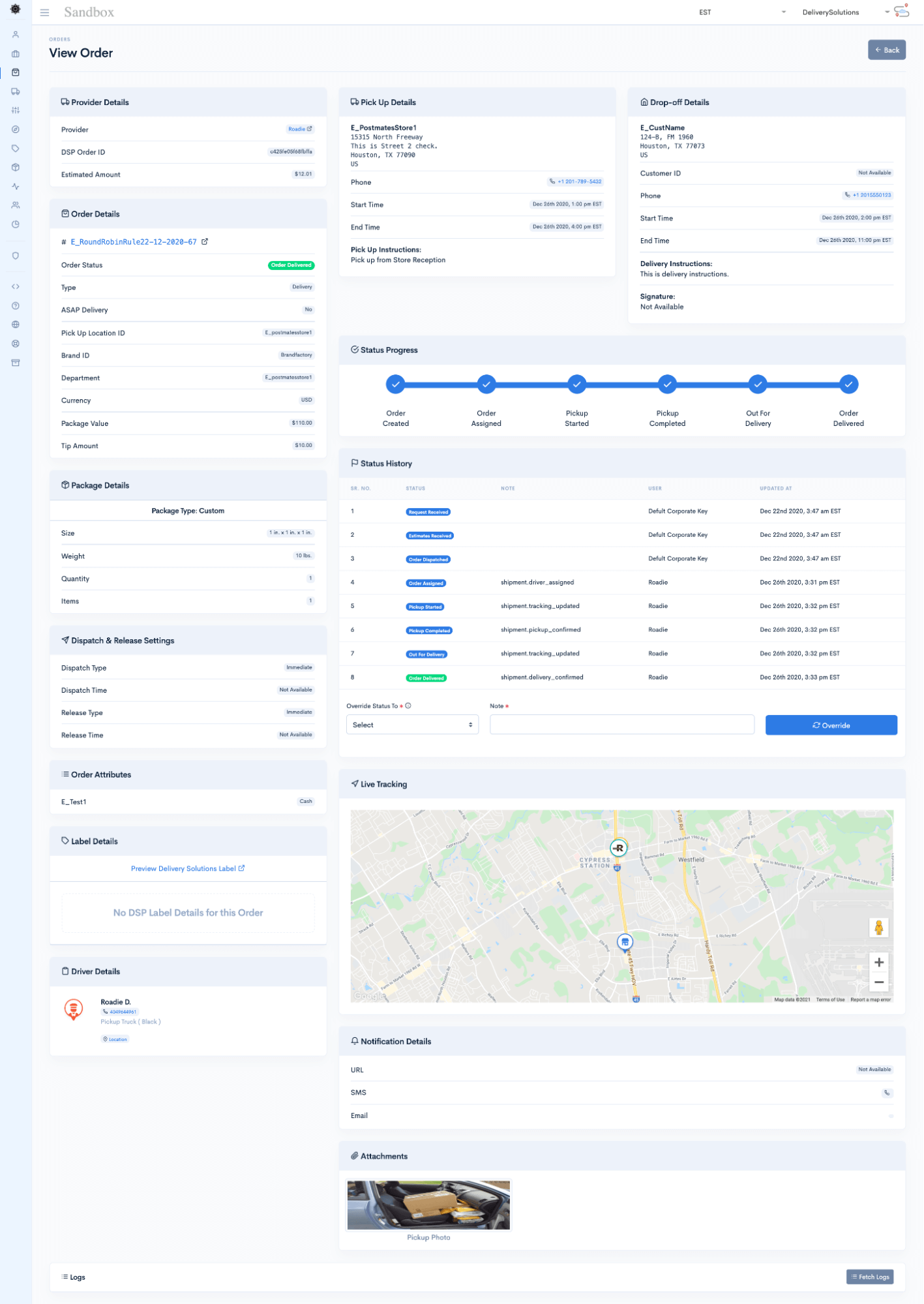

Delivery Solutions' platform offers visibility and versatility for smart trip planning and route optimization.

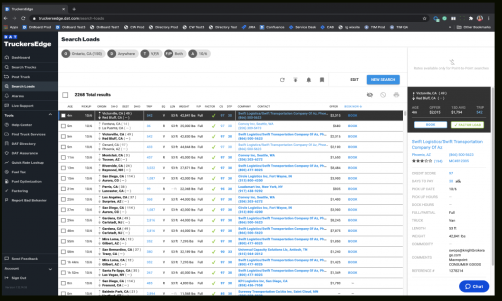

Secure backhaul with load matching

One way to post or find available backhaul along a delivery route is through load boards such as the DAT Network.

Shippers also work with freight brokers, such as C.H. Robinson. Freight brokers match shippers with available truckers or carriers looking for backhaul.

Finally, freight networks or marketplaces like Convoy combine load boards and freight brokers. Freight networks allow shippers and carriers/drivers to connect in real-time. You can match, price quote, bill, pay, and track and manage shipments all through the portal.

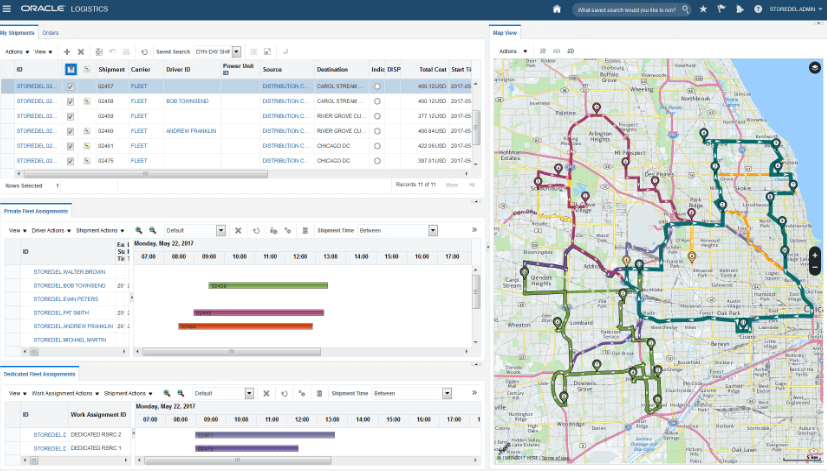

Improve route efficiency with a transportation management system

Transportation management systems (TMS) help shippers and carriers plan, organize, and optimize routes. Dashboards like Oracle's offer real-time route visibility, tracking, and communication between relevant parties.

They also facilitate smart trip planning. They can help prepare for tolls, traffic, severe weather forecasts, construction, and road closures/reroutes. TMSs can minimize possible surprises for drivers while en route.

A TMS also helps with load matching through algorithmic load bundling. A customizable search automatically matches carriers with compatible backhaul when selecting a route. The algorithm finds matches based on route, equipment, truck specs, and schedule.

Freight Management Systems and Uber Freight are examples of TMSs with load bundling technology.

Strengthen your tech stack with an omnichannel experience management platform

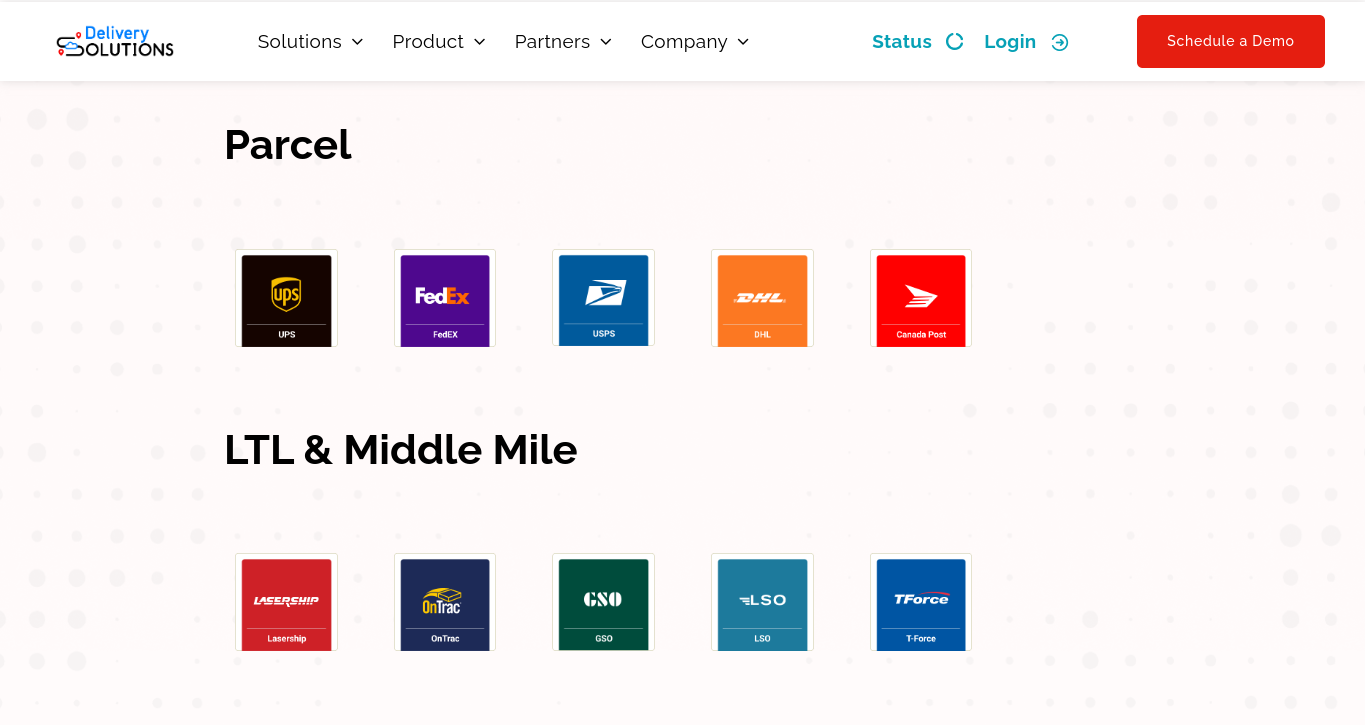

Delivery Solutions offers an omnichannel experience platform.

This software integrates with a company's pre-established TMS and the rest of its e-commerce tech stack. It draws and knits together all elements of the order fulfillment journey under one connected platform. In doing so, it orchestrates, supports, and enhances the entire infrastructure.

Shippers and carriers can streamline fulfillment, ensure on-time delivery, and decrease deadhead mileage through Delivery Solutions. It partners with the world's top delivery providers and is trusted by dozens of leading retailers.

Reap the benefits of decreased deadhead miles

Deadheading is expensive, dangerous, unsustainable, and significantly inefficient.

Delivery Solutions has devoted themselves to building a remedy to this problem. Cutting-edge technology decreases deadhead miles with improved communication and more intelligent, sleeker processes.

Retailers and carriers have more help now than ever in their collaborations through 3PL partners. They cut costs, increase efficiency, prioritize safety and sustainability, and improve customer satisfaction.

The platform by Delivery Solutions orchestrates fulfillment experiences for enterprise retailers. It supplies flexible options for consumers and priming merchants for innovation at scale.

Contact us today to learn how Delivery Solutions can take your logistics systems to the next level!

Ryan Caldarone

Ryan is a Sr. Digital Marketing Manager with over ten years of experience in B2B eCommerce, specializing in brand storytelling and content. Having contributed to hundreds of creative projects for SMBs and startups across the tech, energy, and fine arts sectors, Ryan brings diverse perspectives.

Topics from this blog: 3PL

(

(