With over 2.1 billion global online shoppers and an estimated $6.7 trillion in online retail sales by the end of 2023, the e-commerce industry has become more important than ever.

In a bid to remain competitive, e-commerce brands have had to offer faster delivery times. Most customers now expect their orders to be processed as soon as they click the "buy" button. This trend has put immense pressure on the logistics industry to continually improve their delivery processes and keep up with customer demands.

In this article, we’ll discuss middle-mile logistics, the difference between first-mile, middle-mile and last-mile deliveries, why middle-mile logistics are important, common challenges faced in this stage, and tips to improve your middle mile deliveries.

What is middle-mile logistics?

Middle mile logistics refers to the transportation of goods between the supplier warehouse and the fulfillment centers. It's a critical component of the overall supply chain, and it plays a vital role in ensuring that products reach their destination in a timely, efficient, and cost-effective manner.

It involves the management and coordination of multiple modes of transportation, including trucks, rail, and air, as well as the management of inventory and storage at various points along the way.

As this portion of the delivery process deals with the transportation of the most amount of goods, it offers significant opportunities to increase operational efficiency and reduce shipping costs. It can also help to reduce the carbon footprint of transportation by optimizing routes and minimizing the number of vehicles required for transport.

First-mile vs. middle-mile vs. last-mile logistics

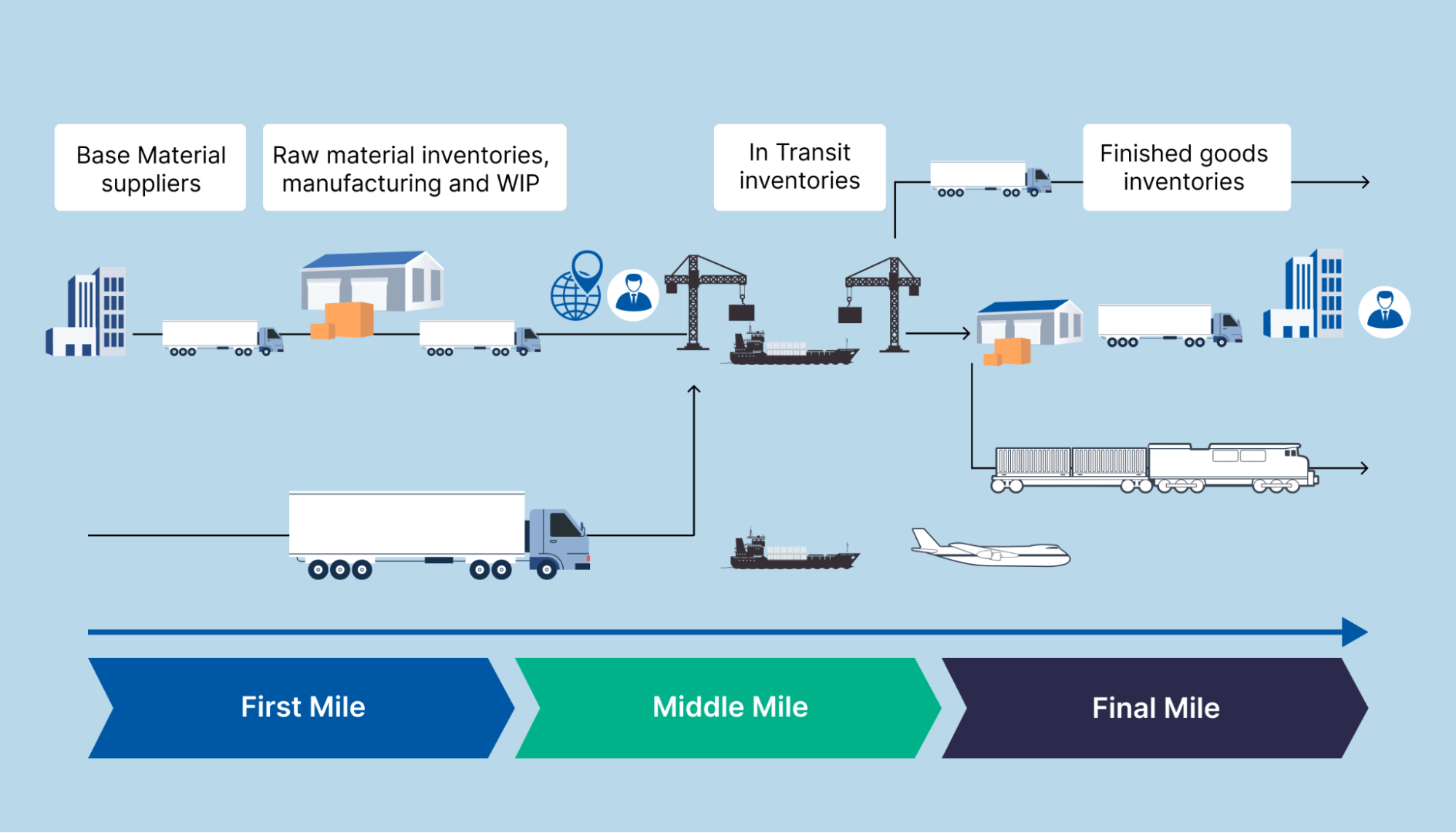

Supply chain logistics is the process of managing the movement and storage of goods from the point of origin to the point of consumption. The supply chain process is divided into three main stages: first-mile, middle-mile, and last-mile logistics.

First-mile logistics refers to the movement of goods from the manufacturer to the warehouse or distribution center. It involves the transportation of raw materials or finished goods from the production site to the first point of storage. First-mile logistics is crucial because it kickstarts the entire logistics process.

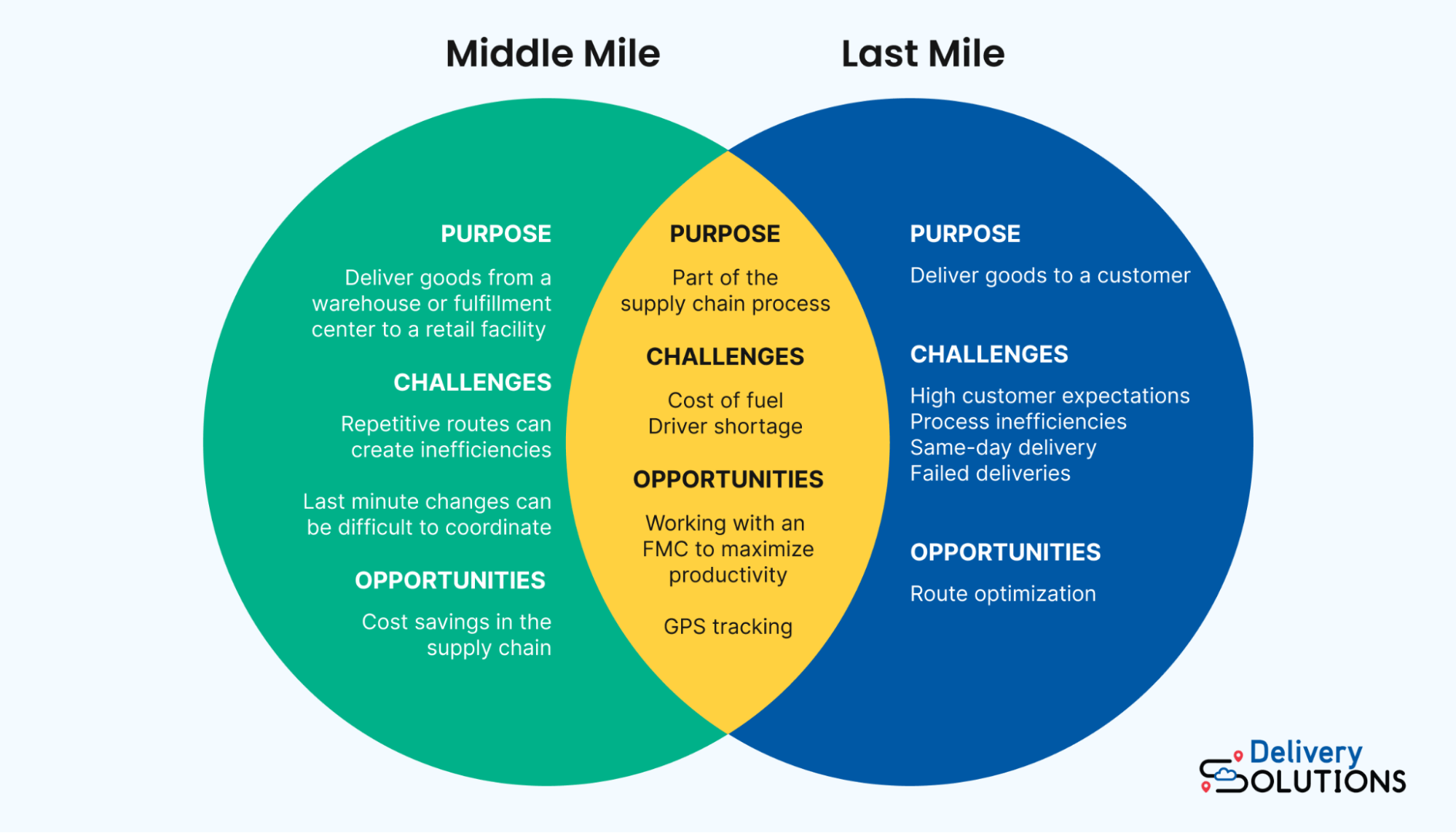

Middle-mile logistics refers to the movement of goods from the warehouse to a fulfillment facility. It involves the transportation of goods from the first point of storage to the distribution center. Middle-mile logistics is important because it involves the movement of goods over longer distances, which can lead to increased transportation costs and longer lead times.

Last-mile logistics refers to the movement of goods from the distribution center to the final customer. It involves the transportation of goods over shorter distances and often requires more complex logistics solutions, such as navigating through congested urban areas or delivering to remote locations. Last-mile logistics is critical because it is the final step in the logistics process, and a positive customer experience is essential for brand loyalty and customer satisfaction.

Each stage of the logistics process has unique challenges and requires specific strategies to optimize efficiency and minimize costs. First-mile logistics requires reliable transportation and efficient warehousing. Middle-mile logistics requires effective transportation management and route optimization. Last-mile logistics requires agile logistics solutions and real-time tracking.

In conclusion, first-mile, middle-mile, and last-mile logistics are all essential components of the logistics process. Effective management of each stage is critical for successful supply chain management and customer satisfaction.

Why is middle-mile logistics important?

Delivery speed is among the top three reasons for cart abandonment, with as many as 35% of customers searching somewhere else if delivery speeds are too slow. That’s only one of the reasons why middle-mile logistics is important. Here are several other reasons:

Connecting the supply chain

The middle-mile acts as a bridge between the first-mile logistics and last-mile logistics. It's responsible for transporting goods over longer distances and ensuring that they arrive at the correct place and time.

Cost-effectiveness

As the middle-mile is often the longest and most bulk-heavy section of the delivery process, it offers huge opportunities for cost-savings. By consolidating shipments and optimizing routes, logistics providers can minimize the number of trips required to move goods, reducing overall transportation costs and carbon footprint.

Efficiency

Mid-mile logistics helps to streamline the supply chain by reducing lead times and improving the time delivery is made. This improves overall efficiency and enables companies to better manage inventory levels.

Middle-mile logistics is critical for ensuring that goods reach their final destination efficiently and cost-effectively. By optimizing middle-mile logistics, businesses can improve efficiency, reduce costs, and scale their operations.

Common challenges associated with middle-mile logistics

Communication breakdowns

Communication breakdowns can happen anywhere on the middle-mile delivery route, from distribution centers to fulfillment centers. Middle-mile logistics are especially susceptible to this issue as it often involves multiple independent stakeholders such as transportation carriers, logistics providers, distribution centers, and warehouse staff.

As the bulk of traffic is moved during this stage, communication can break down due to a lack of standardized communication protocols. Poor data integration can also have a crippling effect on a logistics company’s ability to meet deadlines.

Without a unified delivery system like Delivery Solutions efficient communication can be very difficult to achieve.

Time sensitivity

Another challenge associated with middle-mile logistics is time sensitivity. As products move from the warehouse to the distribution hub, time becomes a critical factor. Scheduled deliveries must arrive on time to ensure that goods aren't left sitting in a warehouse or at a loading dock, which can cause delays and additional costs. Time-sensitive deliveries, such as perishable goods or medical supplies, require even greater attention to detail and coordination to ensure they arrive on time.

Capacity constraints

Capacity constraints can also pose a challenge for middle-mile logistics. As demand for products increases, the capacity for transportation and storage can become limited. This can result in delays and increased costs as logistics providers must find alternative solutions to move goods. Capacity constraints can be particularly challenging during peak seasons, such as holidays, when demand for products is higher.

Data mismanagement

Data mismanagement is another common challenge associated with middle-mile logistics. Logistics providers must manage large volumes of data related to shipments, inventory, and delivery schedules. Without proper data management systems in place, it can be difficult to track shipments, manage inventory, and ensure timely delivery. Data mismanagement can lead to inaccurate tracking, missed deliveries, and additional costs.

Tips to improve your middle-mile delivery

Improve inventory management

Employing good inventory management software in your logistics process allows you to monitor demand and optimize inventory levels to avoid stockouts and overstocking. Analyzing historical data and trends also helps your business forecast future demand, anticipate inventory needs, and plan accordingly.

Creating a regular schedule of physical inventory counts also helps you identify and correct discrepancies in inventory levels. This inspection and testing stage also helps you identify and remove damaged or defective goods from inventory, reducing the risk of delivering subpar products to customers.

Adopt a data-driven approach

In addition to inventory management, adopting a data-driven approach can also help improve middle-mile delivery. By analyzing data related to shipments, inventory, and delivery performance, logistics providers can identify inefficiencies and opportunities for improvement. This can lead to better decision-making, reduced costs, and improved customer satisfaction.

Employ technology solutions

Employing technology solutions is another way to improve middle-mile delivery. Delivery management software such as Delivery Solution’s unified platform help you streamline your operations, improve efficiency, and provide customers with real-time visibility into their shipments. By investing in the right technology solutions, logistics providers can also reduce errors, and offer competitive pricing.

Optimize transportation and routing

Optimizing transportation and routing is another important factor in improving middle-mile delivery. Logistics providers can reduce costs, improve delivery times, and increase customer satisfaction by choosing the most efficient routes, modes of transportation, and carriers. This requires careful planning, analysis of transportation data, adoption of route optimization software, and a willingness to adapt to changing circumstances.

Establish clear communication channels

Finally, establishing clear communication channels with all stakeholders involved in the middle-mile delivery process is crucial for success. This includes carriers, logistics providers, warehouse staff, and other partners. By maintaining open communication, logistics providers can identify potential challenges, proactively address issues, and ensure that all parties are aligned on delivery timelines and expectations.

Conclusion

Middle-mile logistics is an indispensable part of the delivery process. By understanding the importance of middle-mile delivery, its common challenges, and actionable steps, you can increase your ability to deliver on time. This leads to increased profit and customer loyalty.

For most businesses, setting up, optimizing, integrating, and managing your delivery process from the scratch is an impossible and inefficient task. That’s why Delivery Solutions helps you optimize all your logistics with a single connectivity tool, guaranteeing that your packages get delivered on time. For more information click here.

Russ Bair

Russ Bair is the Chief Product Officer at Delivery Solutions, the leading provider of last-mile delivery and fulfillment software. He helps ensure retailers achieve their goals and they are able to provide meaningful experiences for their customers. Prior to his tenure at Delivery Solutions, Russ was President of projekt202—an experience-driven consulting firm founded to apply deep ethnographic research to the development of mobile, web, and workplace software. He received his Bachelors in Computer Science from Texas A&M and has more than 25 years of extensive experience in the software development and consulting fields. While holding leadership roles within organizations or various sizes, Russ has designed, developed, and led the creation of complex custom software implementations for small, medium, and Fortune 500 companies across the United States. Russ is fulfilled by helping those around him reach their potential through servant leadership and collaborating to create progress and economic value. He currently lives in the Dallas area with his wife Jana and two children.

Topics from this blog: Delivery Efficiency Logistics