You want to scale your operations, but managing a warehouse and delivery fleet seems too far-fetched. It’s just not in your wheelhouse.

Luckily, there are plenty of ways to outsource your logistics so that a more experienced outfit can handle your storing, packing, and shipping.

But first, it’s important to understand how the face of logistics is changing so you know which third-party providers to choose.

Read on to learn how logistics outsourcing can help your company evolve and which trends to follow.

What does “outsourcing logistics” mean?

Logistic outsourcing, also known as third-party logistics (3PL), is the process of using an external provider to handle the various functions of your supply chain.

This includes storage and warehousing, product preparation (labeling, folding clothes, etc.), picking and packing, and delivery.

Essentially, it's the physical goods management by an experienced third-party provider.

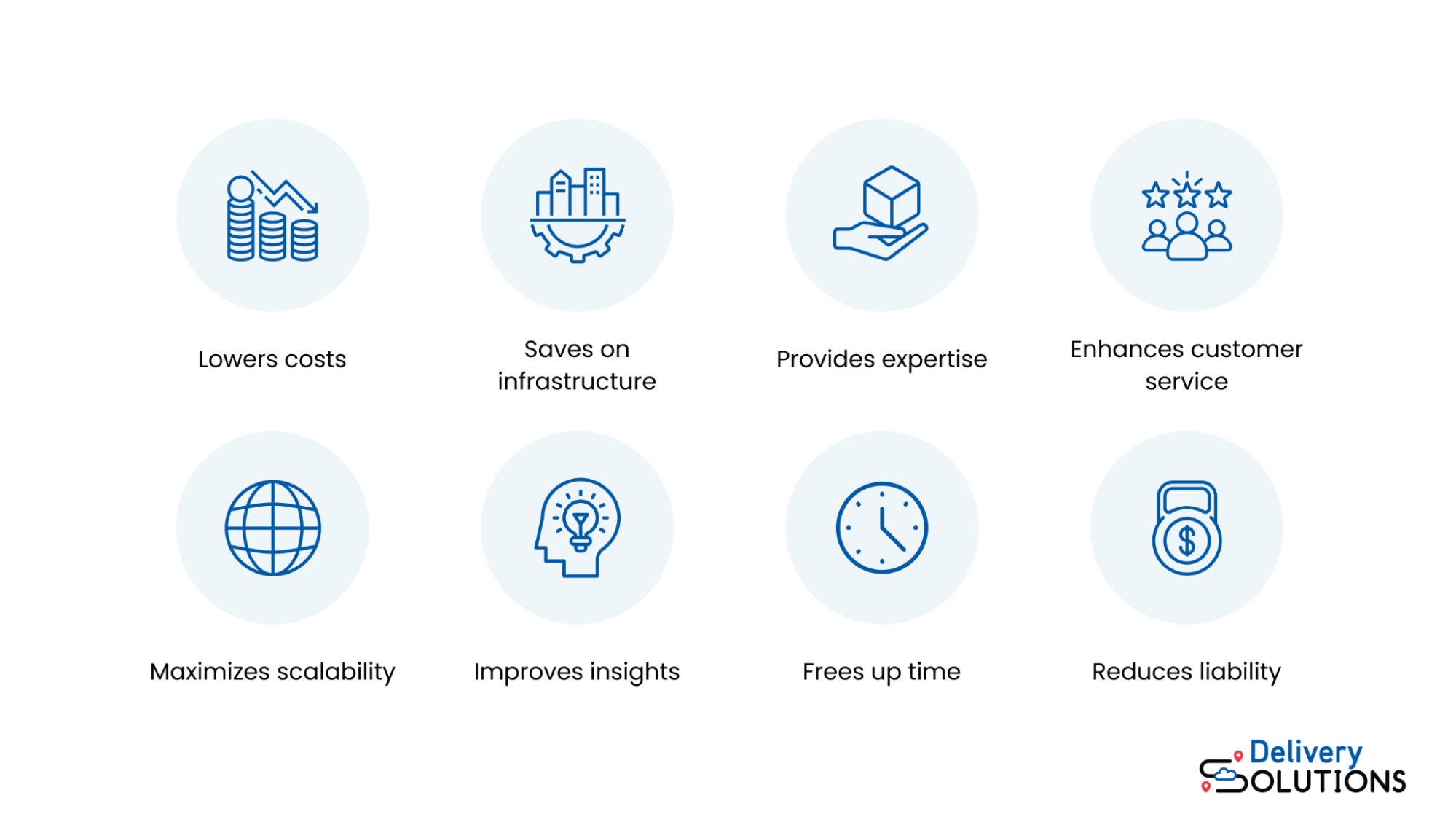

Benefits of outsourcing logistics

There are several advantages to using a third party for your logistics operations.

Not only can you benefit from cost savings, but enhanced reporting and established warehouse operations also lead to smoother supply chain management throughout the entire process.

Here are the key reasons for outsourcing logistics:

Here are the key reasons for outsourcing logistics:

- Lowers costs: 69% of businesses that outsource logistics say it’s lowered overall logistics costs. Large 3PL companies negotiate deals with shipping providers for cheaper freight costs. They also pack vehicles with goods from multiple clients, sharing the freight charges between different companies. On top of that, established third-party logistics companies have tried-and-tested systems, so you’re less likely to spend unnecessary money remedying mistakes.

- Saves on infrastructure: When you build in-house logistics systems, you must buy your infrastructure. It’s expensive to design, set up, and maintain warehouses, vehicle fleets, logistics teams, etc. Third-party logistics services already have this infrastructure in place.

- Provides expertise: 3PL companies specialize in logistics services and have the experience to operate them at scale. This means fewer mistakes and a more effective and efficient system.

- Enhances customer service: 71% of businesses that outsource logistics say customer satisfaction has improved. With the experience and expertise of 3PL companies, there are fewer mistakes and delays, leading to better customer relationships.

- Maximizes scalability: By outsourcing logistics, businesses can leverage the expertise and infrastructure of third-party organizations to handle more inventory and orders. This enables rapid growth without having to create your own logistics systems.

- Improves insights: Experienced 3PLs have advanced systems for reporting and analyzing performance. For example, 81% of third-party logistics companies use inventory and order volume reporting; 46% use labor reporting; and 32% have productivity dashboards. But it’s not just that they have the tools — they also know how to interpret the results. These insights can help businesses make informed decisions for future improvement.

- Frees up time: By outsourcing logistics, businesses can focus their energy and resources on improving core business initiatives, leaving the logistics to the experts.

- Reduces liability: Carrier liability is assumed by the third-party provider, reducing the risk and liability for your business.

Top new outsourcing trends to futureproof your services

To meet customer demands for cheaper and quicker shipping, you must stay on top of industry developments that can fast-track your critical operations. That way, you can pick a reliable company that employs innovative technology and future-forward processes.

When picking a 3PL provider, consider how well they implement the following trends.

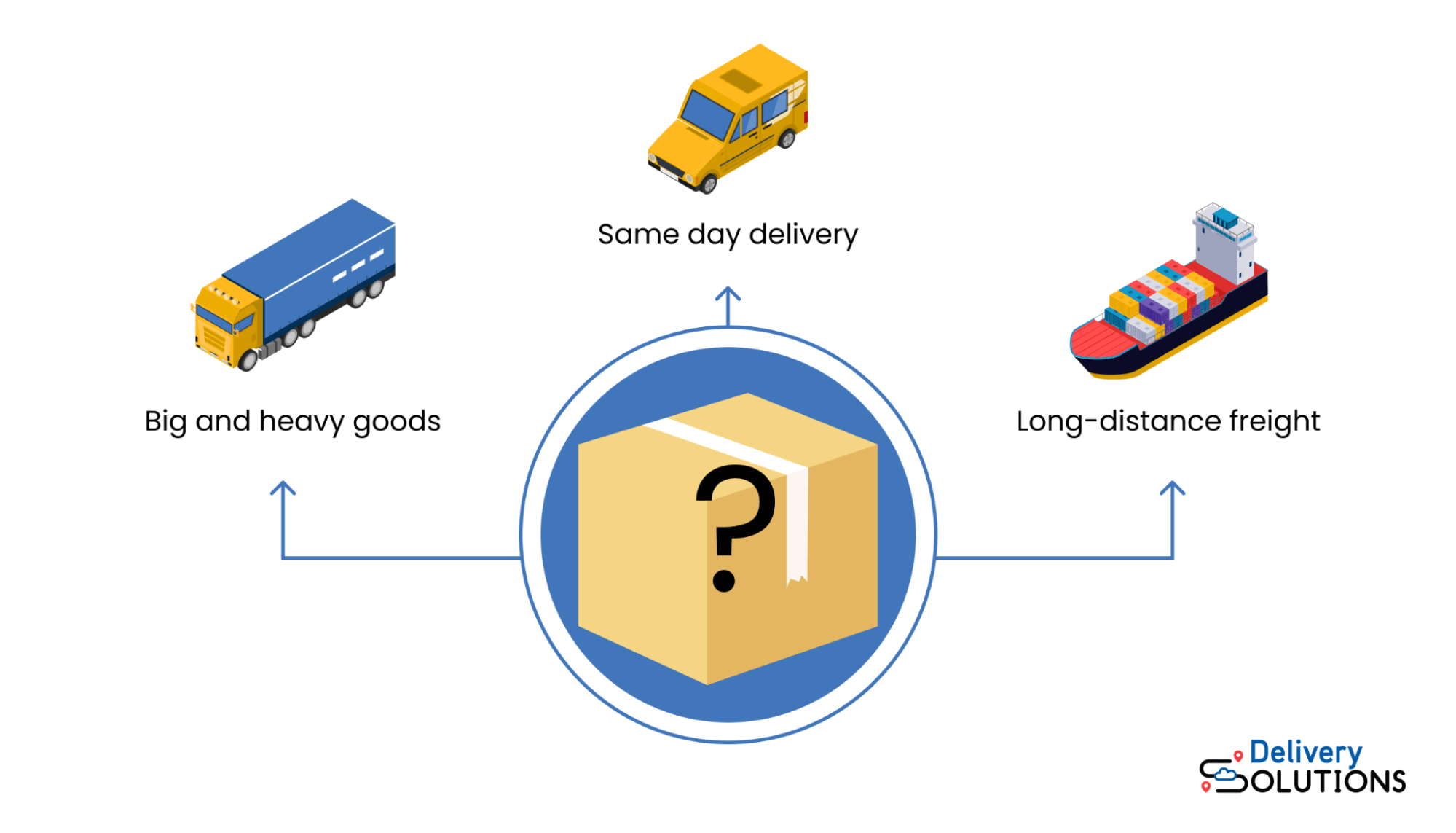

1. Outsourcing logistics to multiple 3PL companies

You limit your operational capacity if you only use one third-party logistics partner.

Some companies don’t offer same-day delivery to certain areas, while others can’t deliver large bulky items or refrigerated goods.

To stay ahead of the competition, businesses opt to use multiple 3PL companies to choose the one most eligible for each location and product.

This stops you from relying on one company that may be too busy or lacks capacity and allows you to test different companies and compare results.

However, juggling multiple logistics specialists can be tricky, with 41% of companies complaining that managing various carriers is one of the biggest pain points.

An automated system like Delivery Solutions can automatically work out customer eligibility and assign the right 3PL company, helping you benefit from multiple providers.

2. Managing reverse logistics

When it comes to ecommerce, customers want the smooth customer journey they experience when shopping on Amazon. This is known as the Amazon Effect, and it now impacts a third of all shippers.

An easy returns process or “reverse logistics” is a major component of this.

To keep up with customer expectations, businesses must have an efficient returns process. If customers find it difficult to return goods, they’ll choose a supplier that makes it easy for them.

Think of it this way. If you’re ordering clothes online, you might order multiple sizes with the view that you’ll return the ones that don’t fit.

If the brand you like best doesn’t offer this option, you will not risk buying the wrong size. You’ll find another clothing outlet that makes it easy to send items back.

Consider offering home collection services or locker drop-off locations. Find a 3PL provider with proven returns processes that match the returns options you’d like to provide customers.

3. Upgrading final mile delivery to acquire customers

Seamless final mile delivery has become a crucial factor in acquiring and retaining customers.

Customers want last-mile delivery to be straightforward, with options for same-day shipping and various pickup points (buy online, pick up in store, lockers, home delivery, etc.).

Not only that, but customers also want delivery to be cheap. In fact, 61% of shoppers say they’d shop elsewhere over paying costly shipping fees.

The problem is that logistics processes aren’t cheap, costing anywhere from $1.40 to $12 an item. Since you can’t pass this cost down to the customer, you must swallow it as a logistics expense.

In this respect, you need a third-party logistics provider that offers custom solutions that fit your logistics outsourcing budget and the shipping needs of your target audience.

4. Improving the environmental impact of logistics

66% of consumers say that sustainability is one of their top five considerations when making purchasing decisions. With this in mind, 3PL providers are reducing their carbon footprint and environmental impact.

For the picking and packing processes, companies are using green packaging to cut down on single-use plastics.

Regarding delivering goods, logistics firms are looking to reduce the impact of gas-guzzling vehicles on the road.

A simple way to do this is to optimize space in delivery vehicles with smarter packing methods. Instead of two half-full trucks on the road, you’re only sending out one.

At the complex end of the scale, some logistics companies are deploying electric delivery vehicles and robotic last-mile solutions that don’t use carbon-based fuels.

Route optimization is another popular strategy to lower carbon footprints. If trucks take more efficient routes, they drive fewer miles, reducing emissions.

It’s also wise to streamline operations. Failed deliveries mean trucks drive unnecessary miles. Real-time tracking and customer/driver communication channels can help to prevent failed deliveries by keeping everyone up to date with any changes.

5. Forecasting customer demand with smart inventory systems

The two most important initiatives for businesses over the next year revolve around balancing demand with supply and improving inventory management.

Using smart inventory management systems and AI-driven tools, 3PL providers can help predict future customer demand.

On the one hand, this helps prevent the complications and extra warehousing costs of overstocking. On the other hand, it reduces the chances you’ll lose conversion opportunities because popular items are out of stock.

Plus, real-time inventory insights enable you to capitalize on upcoming trends.

If a new celebrity trend causes a spike in sales of a previously unpopular product, a smart inventory system will flag the pattern and predict demand. Seeing the movement in real-time means you can order extra inventory to capitalize on the sudden market before the fad passes.

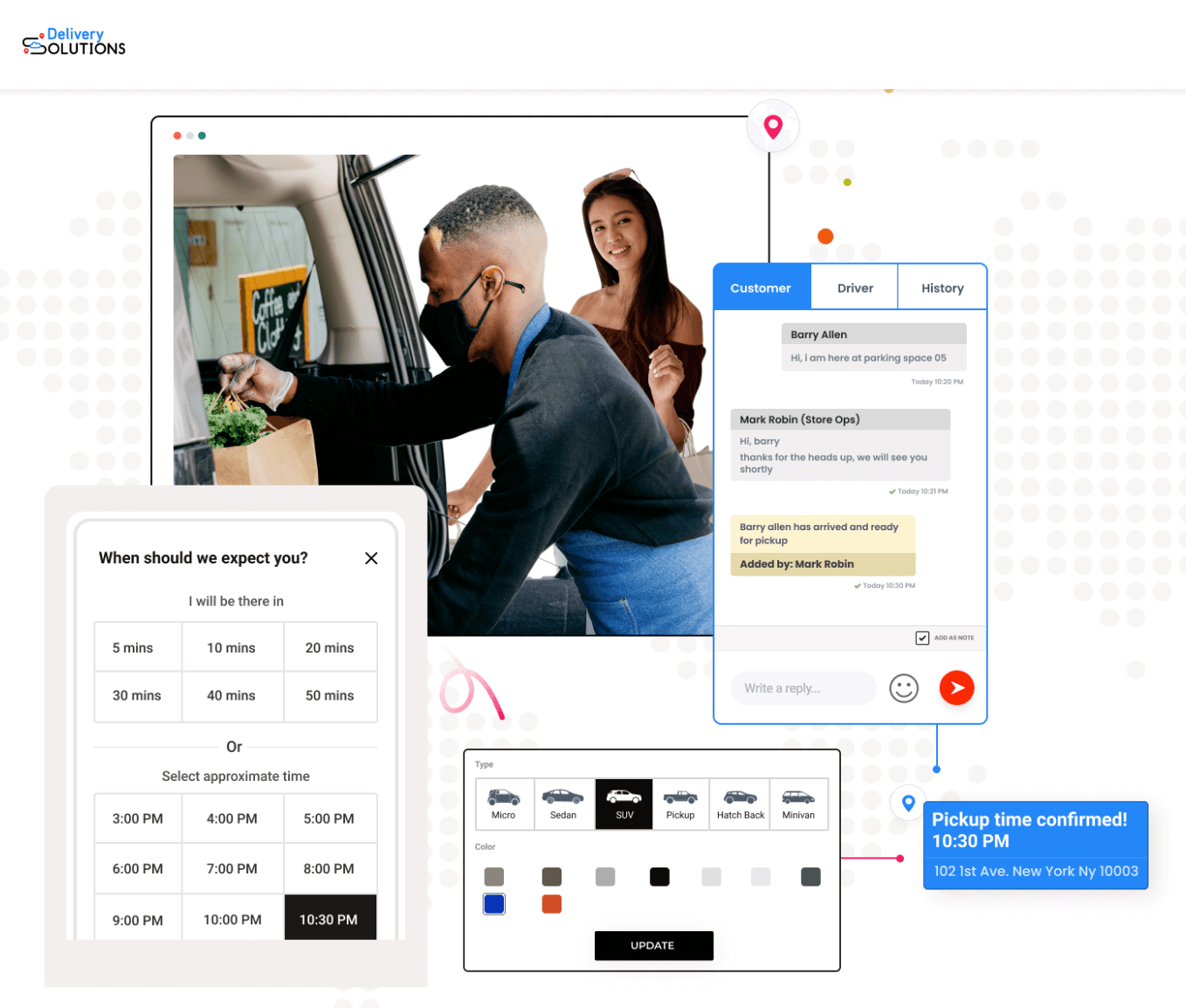

6. Automating customer relations

More than a quarter of companies say that their biggest barrier to offering effective final mile service is the overload of customer support requests that come with it.

When more customers demand support, it can be costly and time-consuming to scale and train human support agents.

Businesses are now using automation to manage customer support requests and facilitate post-purchase communication. This saves money on customer service staffing and makes it easier to scale support and avoid potential reputational damage due to poor communication.

For example, customers who receive automated delivery updates are less likely to call support to ask where their goods are.

7. Omnichannel fulfillment

In the early days of online shopping, customers tended to buy products directly from a brand’s website. Third-party logistics teams only had to handle incoming orders from a single sales channel.

Now, however, companies will sell products across myriad platforms. While you sell your clothes on your online store, you might also offer products through Instagram, Etsy, and Amazon.

With more channels to manage, it can be difficult to keep track of orders coming from all different directions. Despite this, customers must receive the same level of service when receiving goods, no matter which platform they shop on.

Omnichannel fulfillment means having a unified system for managing inventory and processing orders, regardless of the channel you receive them from.

This approach drives growth. While only 25% of 3PL providers offer true omnichannel fulfillment options, the ones that do, have experienced 13% more growth than any other fulfillment type.

In this sense, if you’re looking to scale up your business, you need a 3PL company with established omnichannel processes to pick, pack, and deliver goods from multiple selling channels in a coherent and streamlined way.

8. Outsourcing to fourth-party logistics companies

The fourth-party logistics (4PL) market is set to increase by nearly 25% in the next 5 years, and for a good reason. Where a 3PL service only handles one part of your supply chain, a 4PL company handles your whole operation.

For example, a 3PL provider might store your goods and provide same-day delivery services.

A 4PL provider will also offer these services. But, on top of this, they’ll also manage resources, technology, and infrastructure and provide strategic insights to improve your processes.

Instead of needing a bunch of 3PL firms to handle all aspects of your supply chain, you work with one 4PL provider who deals with everything.

As a single point of contact for all supply chain management, fourth-party logistics saves you money and time by reducing the complexity of your logistical operations.

Handing logistics over to the experts

Not only can logistics outsourcing save you money and improve your existing delivery mechanisms, but it’s also a great way to leverage the resources and experience of supply chain experts.

By employing a third (or fourth) party to manage the storage and shipping of your products, you can focus on the core activities of your business rather than getting bogged down in the logistical practicalities.

Remember though, you’ll need a system that helps you manage and assign jobs to your third-party logistics providers. The unified omnichannel experience platform by Delivery Solutions orchestrates fulfillment experiences like logistics, pickup, post-purchase, and returns for enterprise retailers. This gives them better control over their post-cart brand experience. Demo Delivery Solutions today to see how you can streamline final mile delivery by automating carrier management.

Ryan Caldarone

Ryan is a Sr. Digital Marketing Manager with over ten years of experience in B2B eCommerce, specializing in brand storytelling and content. Having contributed to hundreds of creative projects for SMBs and startups across the tech, energy, and fine arts sectors, Ryan brings diverse perspectives.

(

(